Innovative Reuse

While most of the sediment finds a permanent new home within a containment facility like Masonville, some of the material can be repurposed and used in the development or manufacturing of commercial, industrial, horticultural, agricultural, and other products.

The innovative reuse of Harbor channel material is a key component to the long-term success and sustainability of the Port of Baltimore and continues to be a priority for the Governor, Maryland Department of Transportation (MDOT) and Maryland Port Administration (MPA). And due to strong coordination and collaboration with key stakeholders such as the Dredged Material Management Program (DMMP) Committees, several of the 2014 Innovative and Beneficial Use Strategy’s action items have been advanced or completed.

Moving forward, innovative reuse projects will be based on Maryland Department of Environment criteria that will guide prospective users of dredged material through the various steps, permits, or approvals necessary based on the proposed project, covering sampling requirements, environmental and public health standards, and long-term management needs.

IRBU Web Tool

MDOT MPA is pleased to announce the launch of the new Innovative Reuse and Beneficial Use Web Tool! The web tool is a one-stop-shop for information related to the Port's IRBU Program and includes a form to request dredged material from MDOT MPA.

To learn a bit more about the innovative reuse of dredged material watch the video below.

Beneficial Use

In addition to these innovative commercial reuses, there are other beneficial uses of dredged material which include using it for the restoration of underwater grasses, island restoration, stabilization of eroding shorelines, the creation or restoration of wetlands, and the creation, restoration, or enhancement of fish or shellfish habitats.

Download Fact Sheet

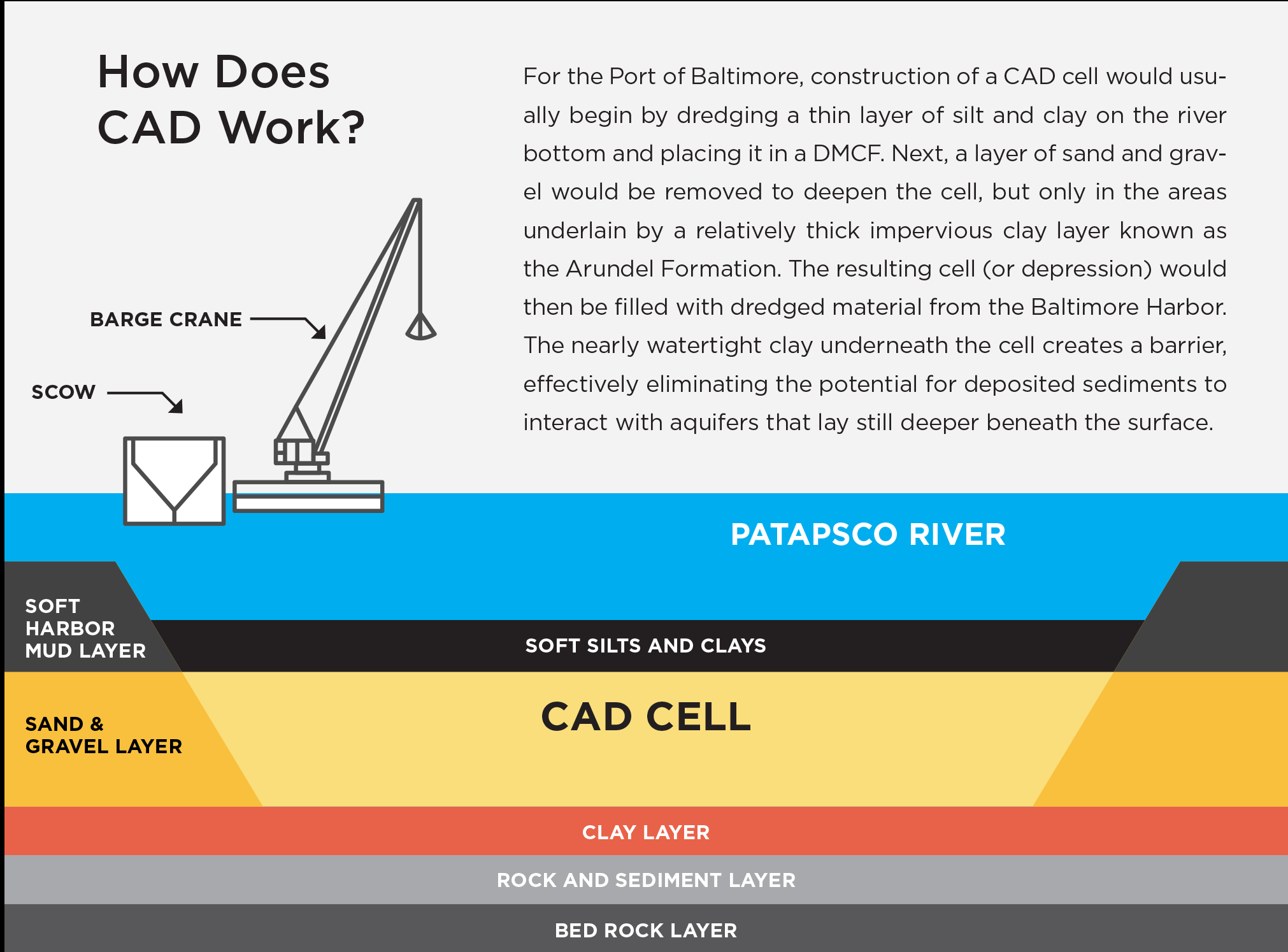

Confined Aquatic Disposal

In addition to diked containment facilities or the above mentioned innovative and beneficial uses of dredged material, there remains a third management option called Confined Aquatic Disposal, or CAD for short. An example of how it works follows: imagine clean sand being dredged from an underwater site and moved to an onshore staging area for reuse as a construction material. What is left behind from the sand's removal is an underwater cavity - the CAD cell - that can then be filled with dredged material. A pilot project was launched in Baltimore harbor in 2016, and has so far shown promising results.