CONFINED AQUATIC DISPOSAL (CAD)

Because finding new placement capacity is a challenge in the Baltimore region, in addition to diked containment facilities and innovative and beneficial uses of dredged material, there remains a third option called Confined Aquatic Disposal, or CAD, that is being investigated as a potential solution for maintenance material dredged from Baltimore Harbor.

What is CAD?

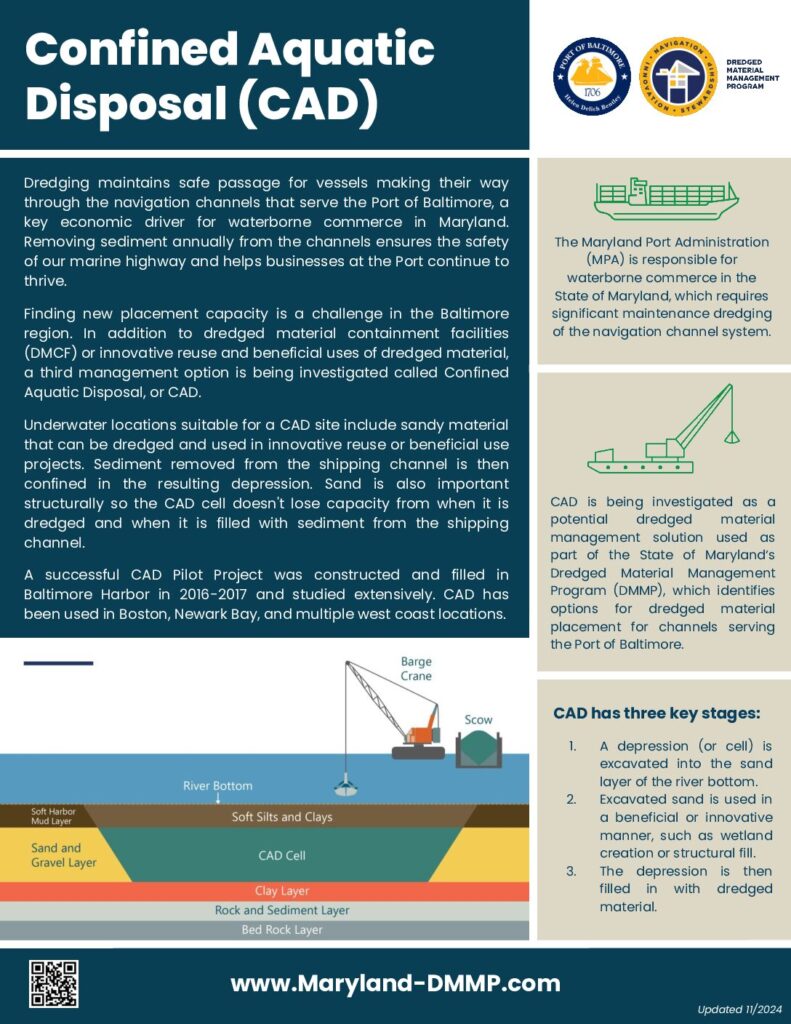

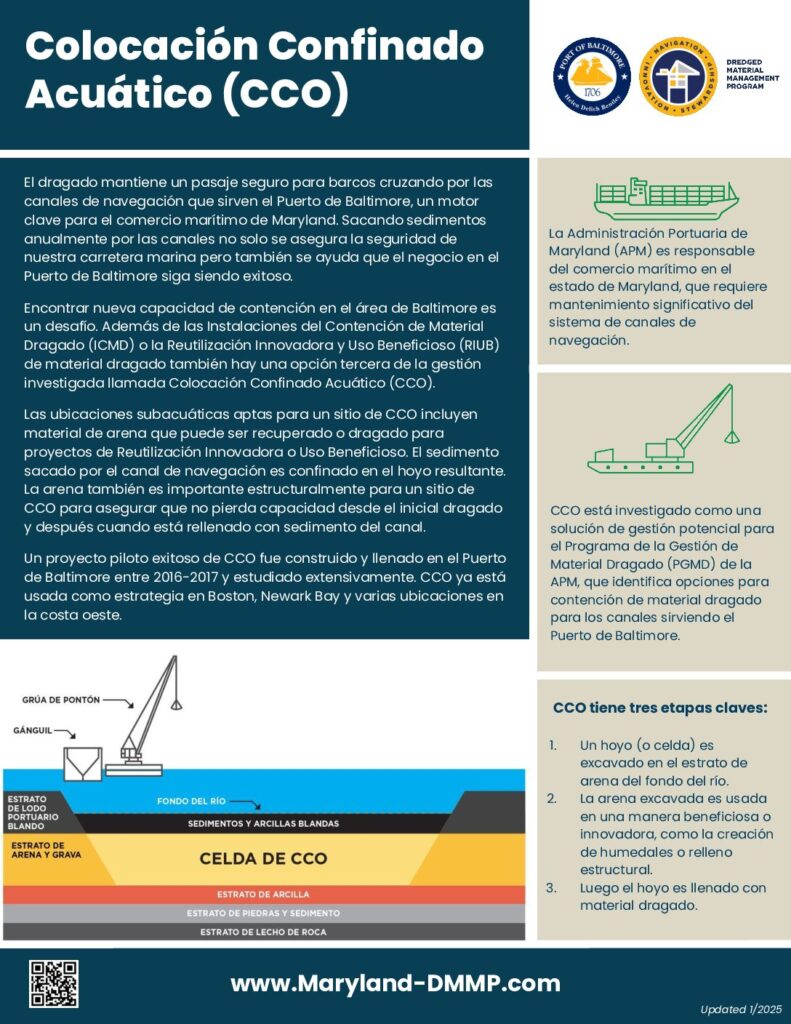

Confined Aquatic Disposal (CAD) is a dredged material management approach that safely places dredged material in an underwater space created by excavating material from the waterway bottom.

For more detailed information on CAD, please download our fact sheet and frequently asked questions:

Newsletter

Spotlight Series: CAD

Fact Sheet

FAQs

How Does CAD Work?

The construction of a CAD cell usually begins by dredging a thin layer of silt and clay on the river bottom and placing that dredged material in a DMCF. Next, a layer of sand and gravel is removed to deepen the cell, but only in the areas that have a relatively thick, impervious clay layer known as the Arundel Formation. Finally the resulting cell (or depression) is filled with dredged material from the Baltimore Harbor. The thick clay underneath the cell creates a barrier, effectively eliminating the potential for deposited sediments to interact with aquifers that lay still deeper beneath the surface. The sand that is removed will be used in nearby construction.

CAD Has Three Stages:

A depression (or cell) is excavated into the sand layer of the river bottom.

Excavated sand is used in a beneficial or innovative manner; such as wetland creation or structural fill.

The depression is then filled in with dredged material.

CAD programs identify suitable underwater locations where sandy material can be recovered/dredged and innovatively or beneficially reused. Sediment removed from the shipping channel is confined in the resulting depression.

With limited dredged material placement capacity at our Harbor Dredged Material Containment Facilities (DMCF), exploring innovative new approaches to dredged material placement in Baltimore Harbor is necessary to maintain the deep water channels of the Port of Baltimore.

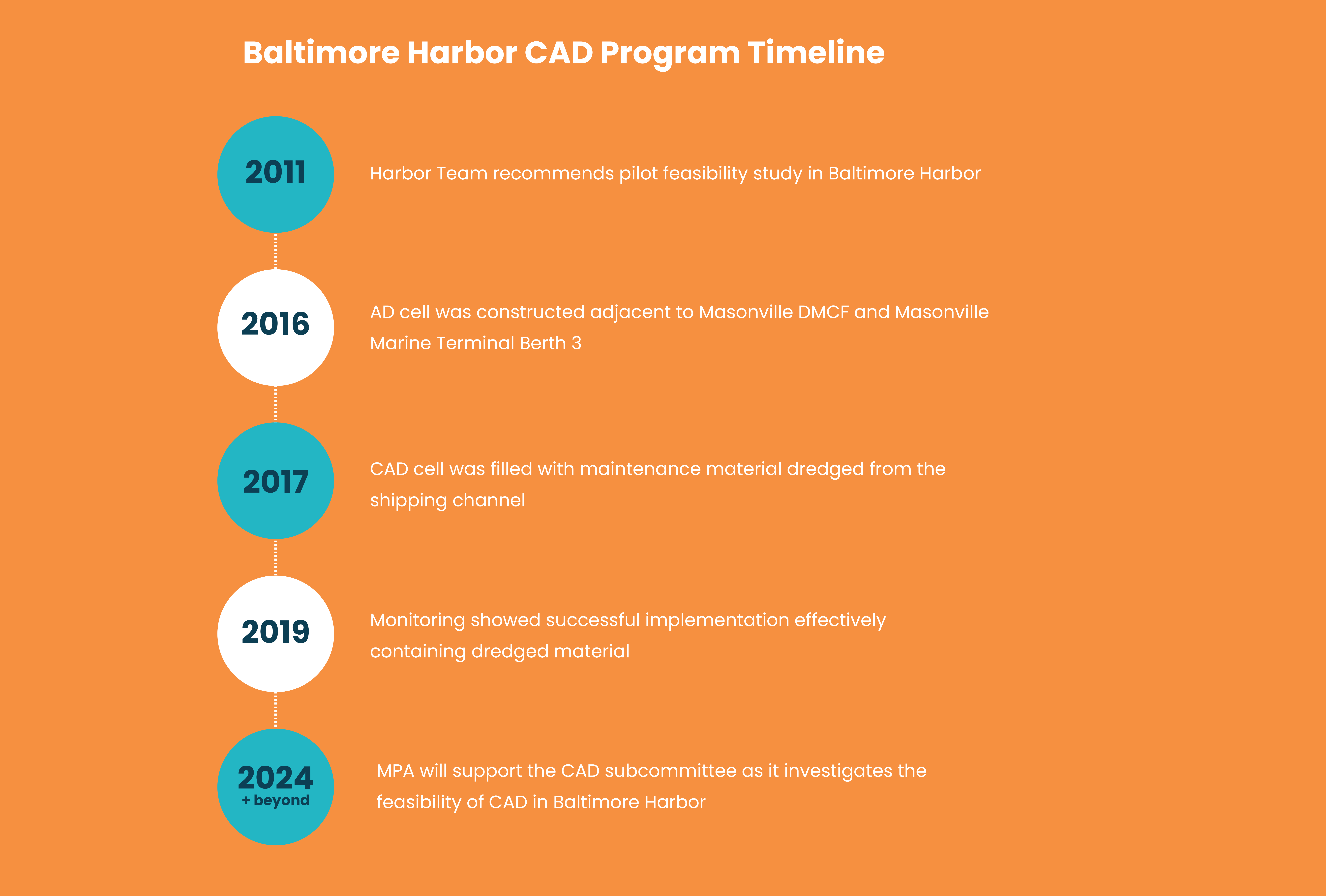

A Successful Pilot Project

In 2016, MPA constructed its first CAD cell in Baltimore Harbor and began an extensive 2-year study of this new approach in Maryland. CAD has been used successfully in other areas of the United States, including Boston and Newark Bay.

The 2016 CAD Pilot Project identified planning goals to be taken into consideration while exploring a second CAD project: evaluate different site conditions that may influence other locations within Baltimore Harbor; operate a larger capacity cell with multi-use or multiple cells within an established area, and determine cost effectiveness.

Preliminary site analysis for a second pilot project included an environmental assessment, hydrodynamic modeling, and geotechnical investigations. The additional evaluations provided additional information to fill in data gaps to assist in future site selection.

Next Steps

Communities have raised concerns about the next CAD pilot project, so the project has been paused to ensure there is a thorough engagement and outreach process. Concerns were also raised by resource agencies, and in response, MPA has reconvened the Bay Enhancement Working Group and formed a CAD Subcommittee to discuss the need for CAD and investigate feasibility considerations, including human and environmental health and safety, cost-effectiveness, and benefits to the State as well as process for site selection of a second pilot project.

If an additional CAD pilot project is deemed feasible and an acceptable site is selected, MPA would work under the oversight of the Maryland Department of the Environment (MDE) in coordination with other State and Federal regulatory agencies to determine if CAD adequately confines dredged material and is safe for the surrounding environment and adjacent communities. Community feedback will be incorporated and addressed throughout the vetting of this alternative method of dredged material management.